Free Specification: Hoists to lift SCR Blocks for Power Plants

Shupper-Brickle Equipment Co

Shupper-Brickle Equipment is pleased to offer the following specification for a hoist used to pick up SCR blocks (selective catalytic reduction) for the purpose of cleaning emissions to meet requirements of the Clean Air Act.

Power Plant Hoist for Lifting SCR Blocks

The Clean Air Act requires fossil fuel power plants to use SCR blocks to remove the NOx from emissions. They weigh about 4,000 lbs each and need to be replaced every five years. So, when a customer asked us for assistance finding the right hoist for this rather challenging lifting requirement, we came up with the following specs for them and are happy to share our findings with anyone needing to lift these blocks. You can read our blog post to learn more about this lifting challenge or stay here for the complete specs.

Downloadable Hoist Specs for Lifting SCR Blocks

Click here for the downloadable version of this free hoist specification.

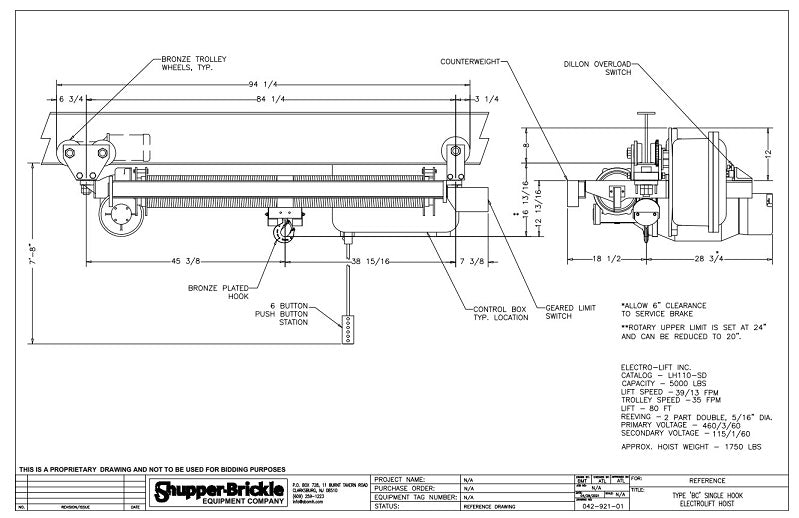

Click here for the Downloadable Hoist Drawing - PDF File.

SCR Hoist Configuration Recommendations

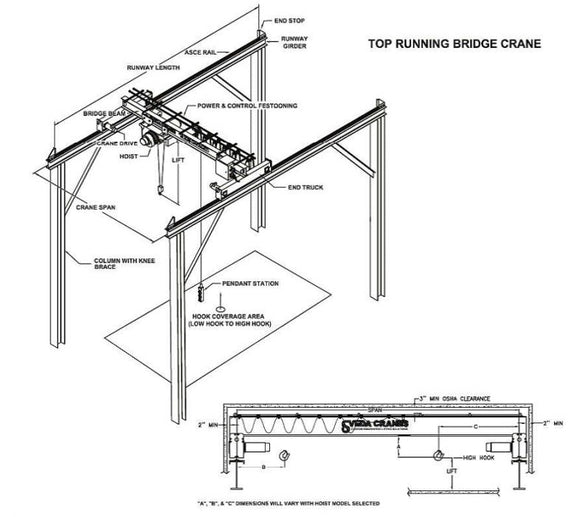

We recommend that the main monorail or drop zone “SCR hoist” be typically configured as follows:

- Brand: Electrolift, low headroom model or approved equivalent of electric wire rope hoist

- Capacity: 5000 lbs. or 6000 lbs.

- Synthetic gearcase lube

- Long lift: 80’ to 90’ from grade to the working level

- True vertical lift: No hook or load drift.

- A geared upper and lower limit, with a final upper limit switch.

- Stainless steel rotation resistant wire rope.

- An overload device, for the protection of equipment and operator.

- Hoisting speed: 39/13 fpm, slow speed for delicate picking and placing, fast for time saving-long up and down lifts and lowers.

- Use across the line starters for hoist, trolley, and mainline contactor. Avoid using VFD’s outdoors, unless the control enclosure is climate controlled.

- 60-minute duty TEFC hoisting motor and continuous duty trolley motor.

- Weather proofing for outdoor use: NEMA 4 or 4X.

- If the area is hazardous (I.E. Class 1, Groups C & D, Division II outdoors,) then the control enclosure should be NEMA 7/4X, with intrinsically safe pendant and limit switches.

- Space heaters in motors and enclosures.

- Drain/breathers in motors and enclosures.

- A six-button pendant: Start/stop; up/down; forward/reverse.

- Epoxy paint, with a topcoat of UV resistant polyurethane.

- A motor driven trolley with a soft start and a motor brake.

- A corrosion resistant festooned electrification system.

- A fused disconnect, at the end of the monorail, within reach of the operator, for emergencies and for lockout.

- A Shupper-Brickle Hoist Shelter parking area, for the five-year storage.

Contact The Hoist Experts!

Since 1969, Shupper-Brickle Equipment has provided bridge cranes, hoists, and custom engineering. Our experienced team provides expert advice on overhead material handling equipment for unusual lifting problems like this one for lifting SCR blocks as well as straight-forward applications. Contact us for more information Our experienced team provides expert advice on overhead material handling equipment for unusual lifting problems like this one for lifting SCR blocks as well as straight-forward applications.