Hoist Overload Devices vs. Thermal Overload Protection - What's the difference?

Andrew T. Litecky

Welcome to The Hoist Guy's Blog, where our resident Hoist Guy Andrew T. Litecky shares his knowledge and experience of many years in the overhead material handling industry to discuss two different kinds of hoist protection devices.

A customer asked us to clarify on similar-sounding hoist parts: What is the difference between hoist overload devices and hoist thermal overload protection?

Hoist Thermal Overload Protection

Thermal overload devices protect hoist and trolley motors against burnout due to excessive heat. They come in two basic forms.

- A thermal overload relay, which has heating elements or an electronic dial in a range of detectors that monitor and react to the current draw.

- A Klix-on or motor thermostat, an electronic device imbedded in the motor windings to sense the actual temperature there.

Thermal Overload Relay

In the case of a thermal overload relay, heating elements or an electronic dial monitor and react to the current draw in all three legs of the motor winding. When the current draw gets too high, a normally closed contact in the “Up” circuit is opened and the load stops going up. The load can be lowered as a safety measure. Thermal overload relays will typically reset themselves automatically when the system cools. Then, operation is permitted to continue.

Klix-On or Motor Thermostat

A Klix-on or motor thermostat is an electronic device imbedded in the motor windings which senses the actual temperature there. When the windings get too hot, the normally-closed contact in the windings opens and the “up” circuit stops. The load can then be lowered.

When it comes to purchasing thermal overload protection, Klix-ons are less expensive than thermal overload relays and save space in the control enclosure. They are also more effective in protecting the motor from burning out. In some hoist and trolley motors, thermal protection is standard and included at no charge. For others, this feature is added at an extra cost.

Hoist Overload Device

Meanwhile, an overload device (without “thermal”) for hoists refers to devices that protect the equipment and operator from lifting a dangerous overload (e.g., a weight higher than the rating of the hoist). The three main types of overload devices are:

- Slip clutch

- Electromechanical overload device

- Electronic overload

Slip Clutch Overload Device

A slip clutch overload device is a simple friction device located in the gear train and factory set to prevent overloads. It’s often found in lever hoists, chain falls, electric chain or air chain hoists, as well as some wire rope hoists. If the hoist is overloaded routinely, the slip clutch will wear over time and the part will need replacing.

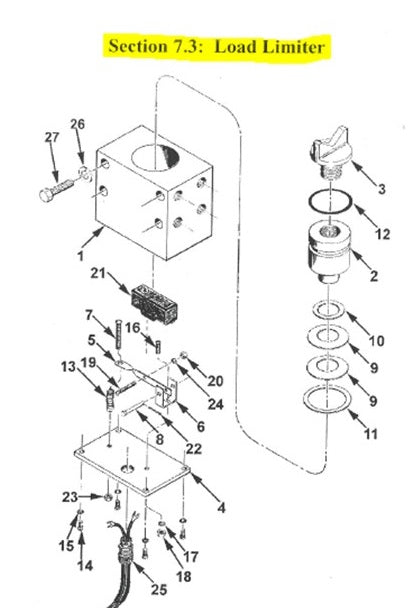

Electromechanical Overload Device

An electromechanical overload device is usually found on wire rope hoists and consists of a “horseshoe” Dillon switch or a stack of Belville washers. Both are connected to the dead end of a single reeved hoist or at the equalizer sheave of a double reeved hoist. This feature has a strong ability to detect an overload, and upon overload the “up” circuit is interrupted. Other electromechanical overload devices include those clamped to a non-moving section of wire rope near the dead ending or equalizer sheaf. This type measures overload through the tension in the wire rope.

Electronic Overload Device

An electronic overload is considered the third type of overload device, and it is found on certain type of Variable Frequency Drives. Certain VFD’s have an overload setting and will stop the load from going up and display a fault code. However, VFD’s cannot auto-reset and must be reset by a technician.

Is it ever okay to overload your bridge crane? Read our blog post to learn more.

Hoists & Accessories from Shupper-Brickle Equipment

Need help finding the right hoist or the right overload protection device for an application? That's our specialty! Contact us here or call 800-642-7263. We supply a wide selection of electronic, air powered and manual hoists as well as OEM hoist parts and accessories.

Since 1969, Shupper-Brickle Equipment has provided overhead material handling equipment to the Mid-Atlantic States and worldwide. We represent a variety of manufacturers and our experienced field service team provides repairs and turn-key system installations. Our in-house engineering department and fabrication team offer customized solutions to solve lifting challenges.