Glossary of Terms: Overhead Material Handling Equipment

Shupper-Brickle Equipment Co

Brush up on keywords and other important terms associated with cranes, hoists and other types of overhead lifting equipment with help from Shupper-Brickle Equipment. We’ve assembled this quick glossary of terms for your reference.

The following definitions for overhead bridge cranes, gantry cranes, hoists and other overhead lifting equipment and mechanisms were obtained from the United States Occupational Safety & Health Administration (OSHA) Standards 1910.179 and the Material Handling Industry of America (MHIA). We also supplemented them with the terms we use every day.

Have a question? Contact us here or call 800-642-7263.

Sources:

Terms Included in Our Overhead Material Handling Glossary

| Abnormal Operating Conditions | Lateral Forces |

| Adjustable or Variable Voltage | Lift |

| Air Hoist | Lift Cycle |

| Automatic Crane | Lifting Devices |

| Auxiliary Girder (Outrigger) | Limit Switch |

| Auxiliary Hoist | Line Contactor |

| Bearing Life Expectancy | Live Load |

| BHN | Load |

| Box Section | Load Block |

| Brake | Load Carrying Part |

| Branch Circuit | Load Cycle |

| Bridge | Longitudinal Stiffeners |

| Bridge Crane | Magnetic Control |

| Bridge Conductors | Main Hoist |

| Bridge Rail | Main Line Contactor |

| Bridge Travel | Main Line Disconnect Switch |

| Bumper (Buffer) | Manual-Magnetic Disconnect Switch |

| CAD | Master Switch |

| Cab-Operated Crane | Match Marking |

| Camber | Mechanical Load Brake |

| Capacity | Mean Effective Load |

| Chain Hoist | Mill Duty Crane |

| Clamp | Multiple Girder Crane |

| CMAA | Non-coasting Mechanical Drive |

| Collectors | Operator's Cab |

| Collector Shoe | Overload |

| Comealong | Overhead Crane |

| Conductors, Runway (main) | Overload Limit Device |

| Contactor, Magnetic | Overload Protection (Overcurrent) |

| Controller | Pendant Pushbutton Sation |

| Counter-torque | Pitch Diameter |

| Cover Plate | Plain Reversing Control |

| Cross Shaft | Plugging |

| Cushioned Start | Protective Panel |

| Crane | Qualified |

| Dead Loads | Rated Load |

| Deflection | Regenerative Braking |

| Diaphram | Regulated Speed |

| Drive Girder | Remote Operated Crane |

| Drum | Resistor Rating |

| Dummy Cab | Rope |

| Dynamic Lowering | Rotating Axle |

| Eddy-Current Braking | Running Sheave |

| Efficiency of Gearing and Sheaves | Runway |

| Electric Overhead Traveling Crane | Runway Conductors |

| Electrical Braking System | Runway Rail |

| Enclosed Conductor(s) | "Shall" |

| Enclosure | Sheave |

| End Approach | "Should" |

| End Tie | Skeleton Cab |

| End Truck | Skewing Forces |

| Fail-safe | Span |

| Field wiring | Static Control |

| Fixed axle | Stepless Control |

| Floor-Operated Crane | Stepped Control |

| Footwalk | Stop |

| Gage | Strength,Average Ultimate |

| Gantry Crane | Sweep |

| Girders | TEFC |

| Ground Fault | TENV |

| Hoist | Torque, Full Load (Motor) |

| Hoist Chain | Torsional Forces |

| Hoist Motion | Trolley |

| Holding Brake | Trolley Frame |

| Hook Approach | Two Blocking |

| Hydraulic Brake | Undervoltage protection |

| Idler Sheave | Variable Frequency |

| Impact Allowance | Voltage Drop |

| Industrial Duty Crane | Wall mounted jib crane |

| Insulation Class | Web Plate |

| Inverter (Variable Frequency Drive) | Wheelbase |

| Jib Crane | Wheel Load |

| K.S.I. | Wireless Controls |

| Kip | Wire Rope Hoist |

| Workstation Crane |

Definitions for Terms Included in our Overhead Lifting Equipment Glossary

Abnormal Operating Conditions:

Environmental conditions that are unfavorable, harmful or detrimental to or for the operation of a hoist, such as excessively high (over 100 F.) or low (below 0 F.) ambient temperatures, corrosive fumes, dust laden or moisture laden atmospheres, and hazardous locations.

Adjustable or Variable Voltage:

A method of control by which the motor supply voltage can be adjusted.

Air hoist:

A suspended machinery unit that is powered by pneumatically driven motors and is used to lift or lower a freely suspended (unguided) load. Generally uses chain or wire rope as its lifting medium.

Automatic Crane:

A crane which when activated operates through a preset cycle or cycles.

Auxiliary Girder (Outrigger): A girder arranged parallel to the main girder for supporting the platform, motor base, operator's cab, control panels, etc., to reduce the torsional forces such load would otherwise impose on the main girder.

Auxiliary Hoist:

Supplemental hoisting unit, which usually provides a lighter capacity and higher speed than the main hoist provides.

Bearing Life Expectancy:

The L-10 life of an anti-friction bearing is the minimum expected life, hours, of 90 percent of a group of bearings, which are operating at a given speed and loading. The average expected life of the bearings is approximately five times the L-10 life.

BHN:

Brinell hardness number, measurement of material hardness.

Box Section:

The rectangular cross section of girders, trucks or other members enclosed on four sides.

Brake:

A device, other than a motor, used for retarding or stopping motion by friction or power means.

Branch Circuit:

The circuit conductors between the final overcurrent device protecting the circuit and the outlet(s).

Bridge:

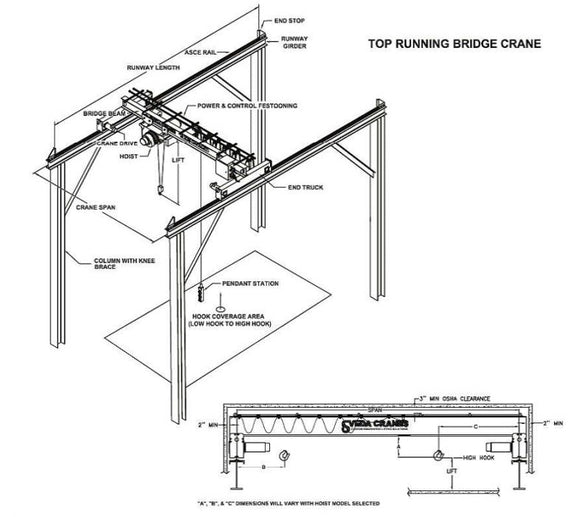

That part of an overhead crane consisting of girders, trucks, end ties, walkway and drive mechanism which carries the trolley and travels in a direction parallel to the runway.

Bridge Crane:

A lifting and horizontal movement device mounted on a "bridge" of one or more horizontal girders (bridge girders) which are supported at either end by trucks (end trucks). These trucks are attached at right angles to the girders and move on runways which are attached to a building's columns, overhead trusses, frames, or via a free standing system of columns.

Bridge Conductors:

The electrical conductors located along the bridge structure of a crane to provide power to the trolley.

Bridge Rail:

The rail supported by the bridge girders on which the trolley travels.

Bridge Travel:

Crane movement in a direction parallel to the crane runway

Bumper (Buffer):

An energy absorbing device for reducing impact when a moving crane or trolley reaches the end of its permitted travel, or when two moving cranes or trolleys come into contact.

CAD:

Computer aided design. A computer software system that allows the user to "draw" and design objects "on a screen" as opposed to the traditional method of drafting and prototyping.

Cab-Operated Crane:

A crane controlled by an operator in a cab located on the bridge or trolley.

Camber:

The slight upward vertical curve given to girders to compensate partially for deflection due to hook load and weight of the crane.

Capacity:

The maximum rated load (in tons) which a crane is designed to handle.

Chain hoist:

Generally, any hoist which utilizes link or roller chain as its lifting medium. Chain hoists can be manually operated (hand or lever), pneumatically driven, or electrically driven.

Clamp:

A below-the-hook attaching device which, using a jaw-like scissor gripping action, clamps or locks onto a piece of material. This device is attached to the hook of a hoist or the end effector of a manipulator and usually is used to pick up sheets of material such as wood or metal.

Clearance:

Minimum distance from the extremity of a crane to the nearest obstruction.

CMAA:

Crane manufacturers Association of America, Inc. (formerly EOCI - Electric Overhead Crane Institute).

Collectors:

Contacting devices for collecting current from the runway or bridge conductors. The mainline collectors are mounted on the bridge to transmit current from the runway conductors, and the trolley collector are mounted on the trolley to transmit current from the bridge conductors.

Collector shoe:

The portion of a collector which makes contact by sliding on the conductor bar.

Comealong:

A common term for a ratchet lever hoist.

Conductors, Runway [main]:

Electrical conductors located along the crane runway to provide power to the crane.

Contactor, Magnetic:

An electro-magnetic device for opening and closing an electric power circuit.

Controller:

A device for regulating in a predetermined way the power delivered to the motor or other equipment.

Counter-torque:

A method of control by which the motor is reversed to develop power to the opposite direction.

Cover Plate:

The top or bottom plate of a box girder.

Cross Shaft:

The shaft extending across the bridge, used to transmit torque from the motor to bridge drive wheels.

Cushioned Start:

An electrical or mechanical method for reducing the rate of acceleration of a travel motion.

Crane:

Machine for lifting and lowering a load and moving it horizontally, with the hoisting mechanism an integral part of the machine. Whether fixed or mobile, cranes are driven either manually or by power

Dead Loads:

The loads on a structure, which remain in a fixed position relative to the structure. On a crane bridge such loads include the girders, footwalk, cross shaft, drive units, panels, etc.

Deflection:

Displacement due to bending or twisting in a vertical or lateral plane, caused by the imposed live and dead loads.

Diaphragm:

A plate or partition between the opposite parts of a member serving a definite purpose in the structural design of the member.

Drive Girder:

The girder on which the bridge drive machinery is mounted.

Drum:

Cylindrical member around which the hoist's wire ropes are wound for raising or lowering the load.

Dummy Cab:

An operator's compartment or platform on a pendant or radio controlled crane, having no permanently mounted electrical controls, in which an operator may ride while controlling the crane

Dynamic Lowering:

A method of control by which the hoist motor is so connected in the lowering direction, that when it is overhauled by the load, it acts as generator and forces current either through the resistors or back into the line.

Eddy-Current Braking:

A method on control by which the motor drives through an electrical induction load brake.

Efficiency of Gearing and Sheaves:

The percentage of force transmitted through these components that is not lost to friction.

Electric Overhead Traveling Crane:

An electrically operated machine for lifting, lowering and transporting loads, consisting of a movable bridge carrying a fixed or movable hoisting mechanism and traveling on an overhead runway structure.

Electrical Braking System:

A method of controlling crane motor speed when in an overhauling condition, without the use of friction braking.

Enclosed Conductor(s):

A conductor or group of conductors substantially enclosed to prevent accidental contact.

Enclosure:

A housing to contain electrical components, usually specified by a NEMA classification number.

End Approach:

The minimum horizontal distance, parallel to the runway, between the outermost extremities of the crane and the centerline of the hook.

End Tie:

A structural member other than the end truck which connects the ends of the girders to maintain the squareness of the bridge.

End Truck:

The unit consisting of the truck frame, wheels, bearings, axles, etc., which supports the bridge girders.

Fail-safe:

A provision designed to automatically stop or safely control any motion in which a malfunction occurs.

Field wiring:

The wiring required after erection of the crane.

Fixed axle:

An axle which is fixed in the truck and on which the wheel revolves.

Floor-Operated Crane:

A crane which is pendant controlled by an operator on the floor or an independent platform.

Footwalk:

The walkway with handrail and toeboards, attached to the bridge or trolley for access purposes.

Gage:

A standard measure for sheet steel thickness or wire diameter.

Gantry Crane:

Crane similar to an overhead crane except that the bridge for carrying the trolley or trolleys is rigidly supported on two or more legs running on fixed rails or other runway

Girders:

The principal horizontal beams of the crane bridge which supports the trolley and is supported by the end trucks.

Ground Fault:

An accidental conducting connection between the electrical circuit or equipment and the earth or some conducting body that serves in place of the earth.

Hoist:

A machinery unit that is used for lifting and lowering a load.

Hoist Chain:

Load bearing chain in a hoist.

Hoist Motion:

Motion of a crane that raises and lowers a load.

Holding Brake:

A brake that automatically prevents motion when power is off.

Hook Approach:

The minimum horizontal distance between the center of the runway rail and the hook.

Hydraulic Brake:

A brake that provides retarding or stopping motion by hydraulic means.

Idler Sheave:

A sheave used to equalize tension in opposite parts of a rope. Because of its slight movement, it is not termed a running sheave.

Impact Allowance:

Additional hook load assumed to result from the dynamic effect of the live load.

Industrial Duty Crane:

Service classification covered by CMAA Specification No. 70, 'Specifications for Electric Overhead Traveling Cranes'.

Insulation Class:

Motor winding insulation rating which indicates its ability to withstand heat and moisture.

Inverter (Variable Frequency Drive):

A method of control by which the fixed line voltage and frequency is changed to a three-phase system with infinitely variable voltage and frequency.

Jib Crane:

A stationary or fixed crane that utilizes a cantilevered bridge (girder) supported from a stationary vertical support. The jib crane generally utilizes a lifting device (hoist) that is mounted on the horizontal boom (jib).

K.S.I.:

Kips per square inch, measurement of stress intensity.

Kip:

A unit of force, equivalent to 1000 pounds.

Knee Brace:

The diagonal structural member joining the building column and roof truss.

Lateral Forces:

Horizontal forces perpendicular to the axis of the member being considered.

Lift:

Maximum safe vertical distance through which the hook, magnet, or bucket can move.

Lift Cycle:

Single lifting and lowering motion (with or without load)

Lifting Devices:

Buckets, magnets, grabs and other supplemental devices, the weight of which is to be considered part of the rated load, used for ease in handling certain types of loads.

A device designed to cut off the power automatically at or near the limit of travel for the crane motion.

Line Contactor:

A contractor to disconnect power from the supply lines.

Live Load:

A load which moves relative to the structure under consideration.

Load:

Total superimposed weight on the load block or hook

Load Block:

Assembly of hook or shackle, swivel, bearing, sheaves, pins, and frame suspended by the hoisting rope

Load Carrying Part:

Any part of the crane in which the induced stress is influenced by the load on the hook.

Load Cycle:

One lift cycle with load plus one lift cycle without load.

Longitudinal Stiffeners:

Horizontal members attached to the web of the bridge girder to prevent web buckling.

Magnetic Control:

A means of controlling direction and speed by using magnetic contactors and relays.

Main Hoist:

Hoist mechanism provided for lifting the maximum rated load

A magnetic contactor used in the incoming power circuit from the main line collectors.

A manual switch which breaks the power lines leading from the main line collectors.

Manual-Magnetic Disconnect Switch:

A power disconnecting means consisting of a magnetic contactor that can be operated by remote pushbutton and can be manually operated by a handle on the switch.

Master Switch:

A manually operated device which serves to govern the operation of contactors and auxiliary devices of an electric control.

Match Marking:

Identification of non-interchangeable parts for re-assembly after shipment.

Mechanical Load Brake:

An automatic type of friction brake used for controlling loads in the lowering direction. This unidirectional device requires torque from the motor to lower a load but does not impose additional load on the motor when lifting a load.

Mean Effective Load:

A load used in durability calculations accounting for both maximum and minimum loads.

Mill Duty Crane:

Service classification covered by AISE Standard No. 6, Specification for Electric Overhead Traveling Cranes for Steel Mill Service.

Multiple Girder Crane:

A crane which has two or more girders for supporting the live load.

Non-coasting Mechanical Drive:

A drive with coasting characteristics such that it will stop the motion within a distance in feet equal to 10 percent of the rated speed in feet per minute when traveling at rated speed with rated load.

Operator's Cab:

The operator's compartment from which movements of the crane are controlled. To be specified by the manufacturer as open, having only sides or a railing around the operator, or enclosed, complete with roof, windows, etc.

Overload:

Any load greater than the rated load.

Crane with a movable bridge carrying a movable or fixed hoisting mechanism and traveling on an overhead fixed runway structure

A device that prevents the equipment and operator from lifting a load weighted higher than the rated capacity of the hoist.

Overload Protection (Overcurrent):

A device operative on excessive current to cause and maintain the interruption or reduction of current flow to the equipment governed.

Means suspended from the crane operating the controllers from the floor or other level beneath the crane.

Pitch Diameter (Rope):

Distance through the center of a drum or sheave from center to center of a rope passed about the periphery.

Plain Reversing Control:

a reversing control which has identical characteristics for both directions of motor rotation.

Plugging:

A control function which accomplishes braking by reversing the motor line voltage polarity or phase sequence.

Protective Panel:

An assembly containing overload and under-voltage protection for all crane motions.

Qualified:

A person who, by possession of a recognized degree, certificate of professional standing or who by extensive knowledge, training, and experience, has successfully demonstrated the ability to solve or resolve problems relating to the subject matter and work.

Rated Load:

Maximum load for which a crane or individual hoist is designed and built by the manufacturer. Maximum rate load are required on the equipment's nameplate

Regenerative Braking:

A method of controlling speed in which electrical energy generated by the motor is fed back into the power system.

Regulated Speed:

A function which tends to maintain constant motor speed for any load for a given speed setting of the controller.

Remote Operated Crane:

A crane controlled by an operator not in a pulpit or in the cab attached to the crane, by any method other than pendant or rope control.

Resistor Rating:

Rating established by NEMA which classifies resistors according to percent of full load current on first point and duty cycle.

Rope:

Generally refers to the use of wire rope, unless otherwise specified

Rotating Axle:

An axle which rotates with the wheel.

Running Sheave:

A Sheave that rotates as the load block is raised or lowered

Runway:

Assembly of rails, beams, girders, brackets, and framework on which the crane or trolley travels

Runway Conductors:

The main conductors mounted on or parallel to the runway which supplies current to the crane.

Runway Rail:

The rail supported by the runway beams on which the bridge travels.

"Shall":

This word indicates that adherence to the particular requirement is necessary in order to conform to the specification.

Sheave:

A grooved wheel or pulley used with a rope or chain to change direction and point of application of a pulling force.

"Should":

This word indicates that the requirement is a recommendation, the advisability of which depends on the facts in each situation.

Skeleton Cab:

Same as dummy cab.

Skewing Forces:

Lateral forces on the bridge truck wheels caused by the bridge girders not running perpendicular to the runways. Some normal skewing occurs in all bridges.

Span:

Horizontal distance center-to-center of runway rails

Static Control:

A method of switching electrical circuits without the use of contacts.

Stepless Control:

A type of control system with infinite speed control between minimum speed and full speed.

Stepped Control:

A type of control system with fixed speed points.

Stop:

Device to limit travel of a trolley or crane bridge. This device normally is attached to a fixed structure and normally does not have energy absorbing ability

Strength, Average Ultimate:

The average tensile force per unit of cross sections area required to rupture the material as determined by test.

Sweep:

Maximum lateral deviation from straightness of a structural member, measured at right angles to the Y-Yaxis.

TEFC:

Totally enclosed fan cooled.

TENV:

Totally enclosed non-ventilated.

Torque, Full Load (Motor):

The torque produced by a motor operating at its rated horsepower and speed.

Torsional Box Girder:

Girder in which the trolley rail is located over one web.

Torsional Forces:

Forces which can cause twisting of a member.

Unit that travels on the bridge rails and carries the hoisting mechanism

Trolley Frame:

The basic structure of the trolley on which are mounted the hoisting and traversing mechanisms.

Trolley Travel:

Trolley movement at right angles to the crane runway

Two Blocking:

Condition under which the load block or load suspended from the hook becomes jammed against the crane structure preventing further winding up of the hoist drum.

Undervoltage Protection:

A device operative on the reduction or failure of voltage to cause and maintain the interruption of power in the main circuit.

A method of control by which the motor supply voltage and frequency can be adjusted.

Voltage Drop:

The loss of voltage in an electric conductor between supply tap and load tap.

Wall mounted jib crane:

May also be referred to as a bracket mounted jib crane. The wall mounted jib crane is attached to the wall of a building by utilizing brackets. These brackets allow the jib to pivot from wall to wall in a given radius. Jib cranes may also be bracket-mounted to columns. These jib cranes usually incorporate tie rods to add stability to the farthest point of the bridge beam.

Web Plate:

The vertical plate connecting the upper and lower flanges or cover plates of a girder.

Wheelbase:

Distance from center-to-center of outermost wheels.

Wheel Load:

The load without impact on any wheel with the trolley and lifted load (rated capacity) positioned on the bridge to drive maximum loading.

Wireless Controls:

Just as the name denotes, these controlling devices utilize laser, radio and infrared medium to a relay information to various types of material handling equipment.

Wire Rope hoist:

A hoist that utilizes wire rope as the lifting medium. Often powered electrically or pneumatically. This lifting device is made up of a rope storage drum, motor(s), gear box and braking system and is suspended from a monorail or bridge beam(s) by means of a trolley. May also be mounted in a stationary manner. Manual wire rope hoist are generally referred to as "pullers" and operate utilizing a ratchet and pawl tensioning technology.

Workstation Crane:

An overhead crane generally used for ergonomic purposes and consisting of bridge(s) and runways made from enclosed metal track. End trucks attached to the bridge girder allow for ease of movement. The entire system is designed to allow workers to move loads by hand pushing the load with the assistance of a vertical lifting device such as a hoist or vacuum lifter.

Bridge Cranes & Hoists Since 1969

Shupper-Brickle Equipment has provided bridge cranes, hoists & engineering expertise to the Mid-Atlantic States and worldwide since 1969. We offer hoist and crane sales, comprehensive services, safety inspections and expert engineering at competitive pricing. Contact Shupper-Brickle Equipment for more information on overhead cranes or gantry cranes. Read our blog post on Bridge Cranes Vs Gantry Cranes.