Hazardous Location Bridge Crane for a Texas Gas Generating Facility

Andrew T. Litecky

Welcome to The Hoist Guy's Blog, where our resident Hoist Guy, Andrew T. Litecky, shares his knowledge and experience of many years in the overhead material handling industry. This time to talk about how our bridge crane specialists were able to fabricate a special system to meet the needs of a hazardous location that was outdoors.

Bridge Crane for Outdoor & Hazardous Environment

An engineering firm recently approached us to fabricate a special bridge crane lifting system for a natural gas generating facility. This maintenance crane was needed to lift head assemblies while outdoors in Texas at a hazardous location qualified as Class 1, Groups B,C, & D, Division 2. Further, the delivery date was critical so the plant could be up and running on schedule. For complex applications like this one, industry knowledge and engineering experience are key to providing the right equipment for the job.

Engineering the Specialty Bridge Crane

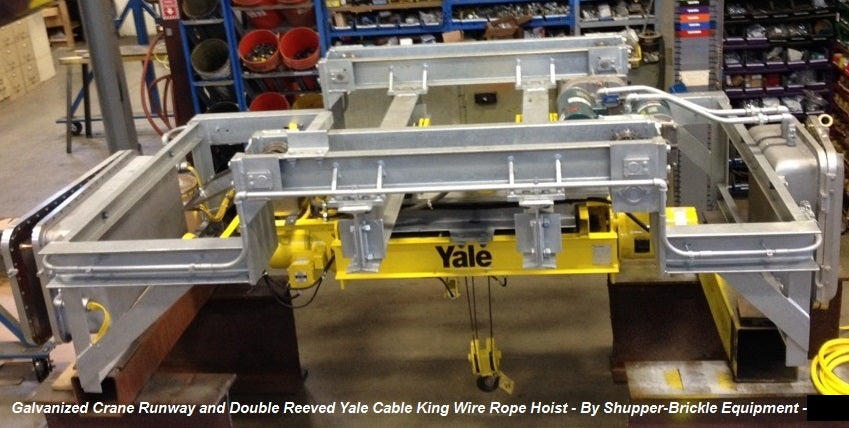

The system was built around a four foot to six foot span double-girder, underhung bridge crane of two ton capacity, and our in-house engineering department calculated all of the loadings and deflections.

A Yale Cable King hoist was selected with parallel mounting and double-reeving for true vertical lift. This ensured precise lifting of the load and prevented hook block drifts. An overload device offered further safety. While Cable Kings offer tight tolerance and end approaches as standard, this hoist was also manufactured with special features, such as a double-girder underhung trolley. The total hook movement was two feet, three inches.

Hazardous Location Specifications

For the specs of this hazardous location, we provided special disconnects and remotely mounted controls. Neoprene festooning was a must for heavy-duty usage where conductor bar could not qualify as explosion-proof.

Outdoor Location Specifications

But the toughest factor in the project was the outdoor location and the Texas climate. To combat the elements, the runway was galvanized and the hoist and trolley were covered with epoxy paint and a urethane top coat. The hoist motor and control panel were outfitted with hazardous location drain breathers, or specialty vents that allow moisture, such as from humidity, to come out but prevent debris from coming in.

Despite many complicated aspects, the equipment met spec and shipped on time. For jobs like this one, we are able to accommodate our customers through access to the industry’s best brands and by offering in-house engineering support.

Shupper-Brickle Equipment’s Bridge Crane Specialists

Shupper-Brickle combines over 50 years of hoist and crane industry experience with a full-service engineering department to offer a range of customized crane and material handling services. We can help you find the right explosion-proof hoist or crane to operate safely in your extreme or hazardous location. Contact us for more information on overhead lifting equipment, or read more about our support services for architects and engineering firms.