The Science & Art of Overhead Crane Engineering: Looking Back on the Career of a Crane Engineer

Shupper-Brickle Equipment Co

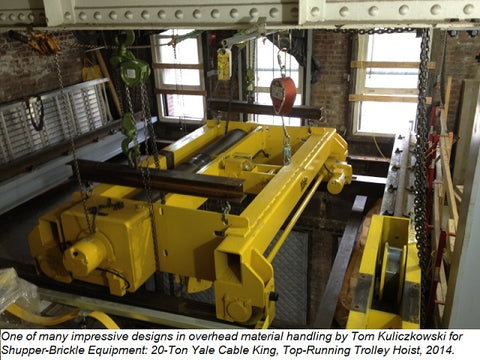

Welcome to The Hoist Guy's Blog! In this post, we spoke with retiring crane engineer Tom Kuliczkowski, the chief engineer at Shupper-Brickle Equipment, about his career highlights and advice for the next generation.

Tom Kuliczkowski started working as a crane engineer in 1977. Back then, material handling systems were designed on drafting tables, communications were typed on typewriters, and there was no such thing as making calculations with software. But some things haven’t changed in 40 years: A good crane engineer needs both technical know-how and creativity to find the best solution for the customer.

Crane engineers design material handling systems for overhead lifting and solve problems with structural, mechanical, and electrical elements. They work within each customer’s constraints, and their knowledge of industry equipment is crucial. We asked Mr. Kuliczkowski about the highlights of his career and his advice for future generations of crane engineers.

What were the most memorable projects of your career?

“When I first started out, I worked on a window-washing machine for the top of the PECO building in Philadelphia, and you can still see it there on Google maps. I was part of the rebuild on an impressive boom crane at the Aker Kvaerner Philadelphia shipyard, and later, I worked on an estimating team for the install of 10-Ton box-girder crane with a 70-foot span in Central PA. Here at Shupper-Brickle, my favorite was a top-running double-girder bridge crane with three hoists and a remote control panel. These projects involved a lot of decisions, but with each job, you build up experience and learn more.”

What changed most about your job and the industry since you started working as a crane engineer?

“Technology has made the biggest difference. Auto-CAD and e-mail have changed key aspects of the job. But there’s still no substitute for real field experience. Throughout the years, no matter where I went or what I worked on, I was always looking around for ideas. Taking the time to examine mechanical systems, even in a different industry, can help spark a solution on a future project.”

What do you want young engineers to know about crane engineering?

“Mostly to learn as much about the industry as you can and from different angles. Taking on different types of work, whether it’s design, calculations, or project management, can really develop your professional skills and help you better understand the industry. Besides, they haven’t yet invented a better way to pick up heavy things. As long as there are cranes, we’ll need crane engineers.”